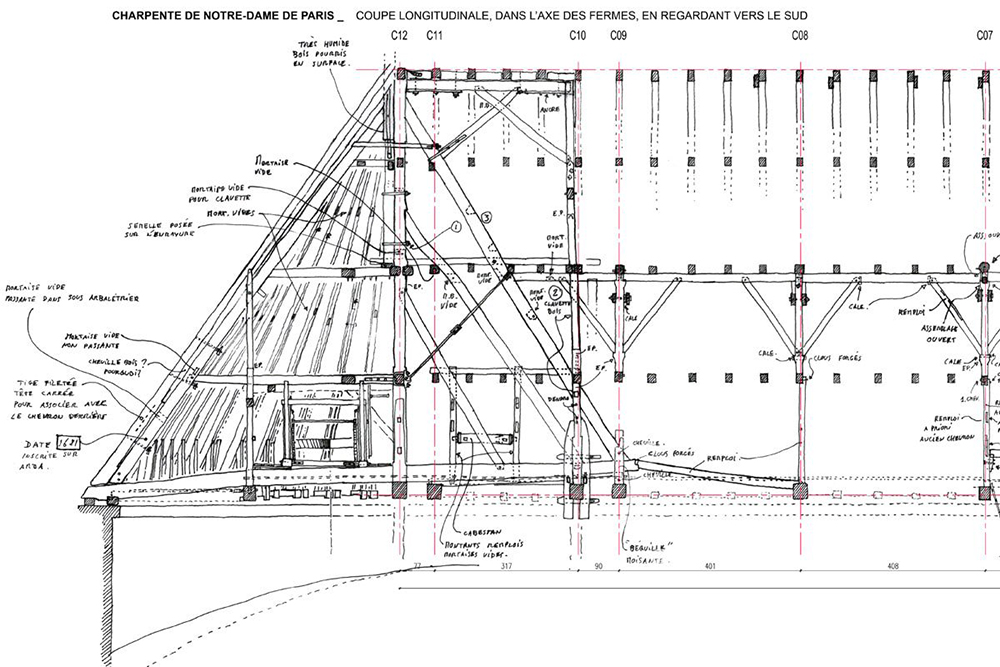

Longitudinal section of the attic. Survey by Rémi Fromont and Cédric Trenteseaux, 2014

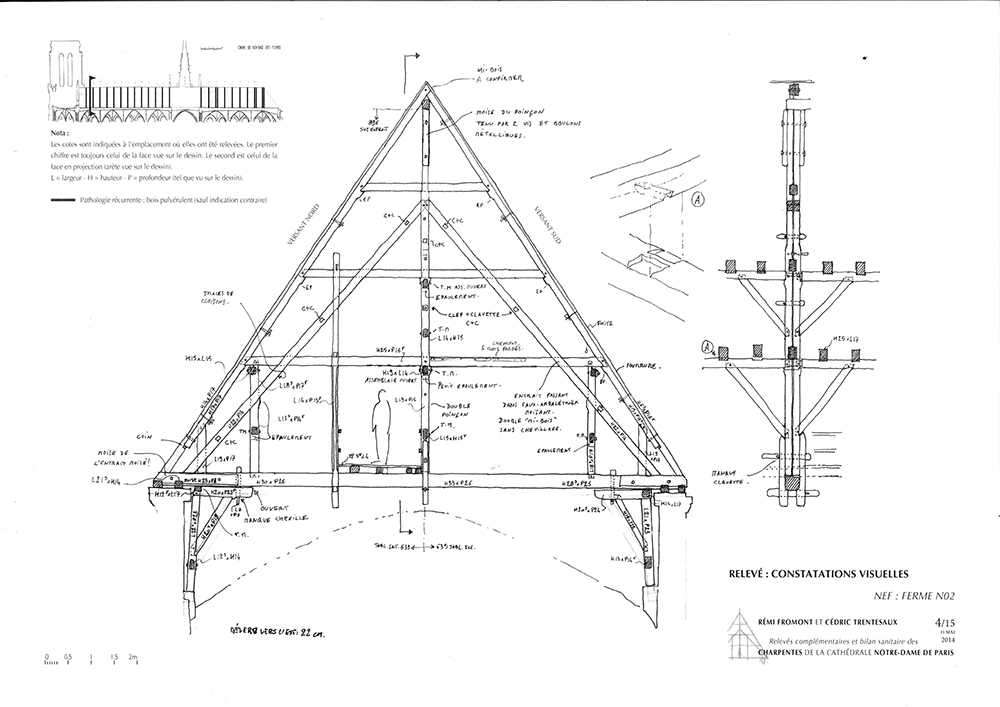

Frame of the nave. Survey by Rémi Fromont and Cédric Trenteseaux, 2014

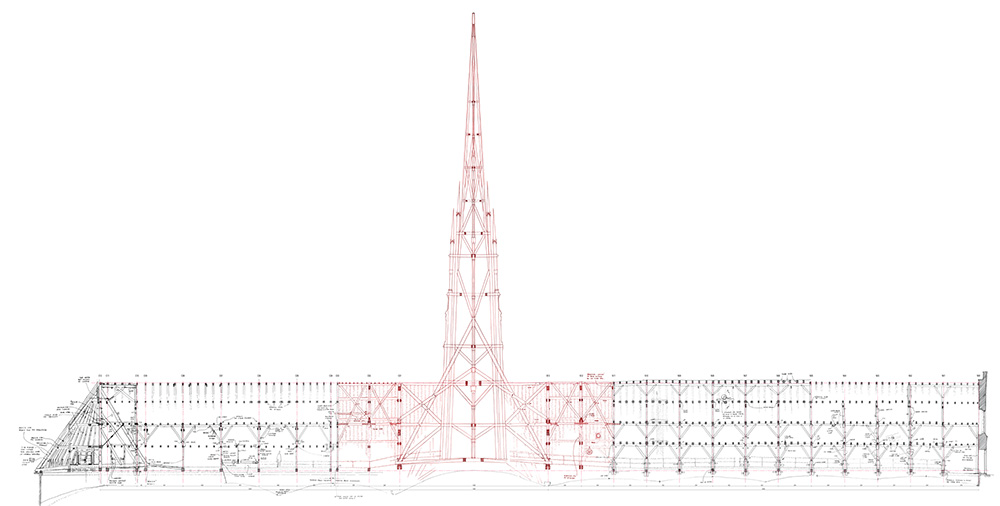

Choir frame. Survey by Rémi Fromont and Cédric Trenteseaux, 2014

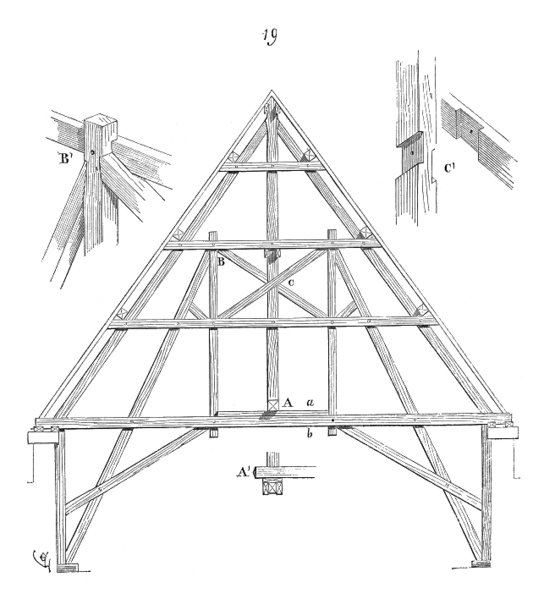

Transept framework © Viollet-le-Duc, Dictionary

Restoration of the Frameworks and Roofings

Benjamin Mouton

Medieval frameworks 12th-13th century

The original choir frame, from 1185, was replaced around 1226; that of the nave was built in 1214. These two frames are made of parallel trusses close together, called "truss rafters". The nave had 57 trusses spaced at 0.71m; the choir had 33 trusses (+24 for the traffic circle), spaced at 0.80m. The span was respectively 14m and 12.50m, for a height of about 12.25m.

Each frame was built from west to east, with successive improvements, more numerous in the choir. They then received structural reinforcements in the 16th or 17th century, and repairs in the 19th century.

Thanks to the very precise surveys, it is possible to reconstitute each farm with all its details of construction and reinforcements.

In June 2020, carpenters cut a truss for the nave from an oak tree felled six months earlier, identical in its dimensions, sections (decreasing towards the top), joints (tenons and mortises), and tools (carpenter's axes). It took only seven days to complete; it was then erected in front of the cathedral. The result is an exact reproduction of the disappeared framework and will allow the exercise of a faithful restitution.

The 19th century frameworks: 1855-1858, 1860-1862

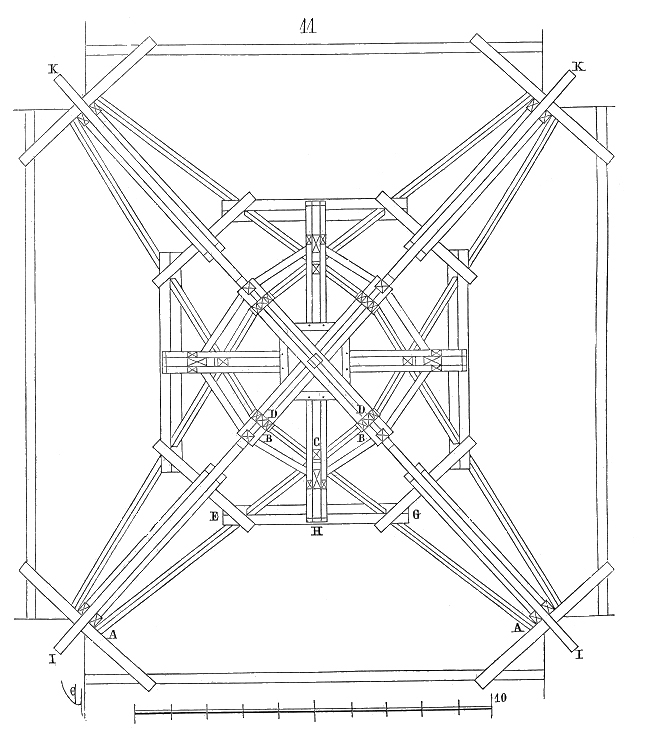

To restore the two north and south gables of the transept and the spire, Viollet-le-Duc had to remove the medieval frameworks and replace them with a framework of trusses spaced 5.50m apart and connected by purlins. The analysis showed that he was inspired by the layout of the trusses of the nave in designing them.

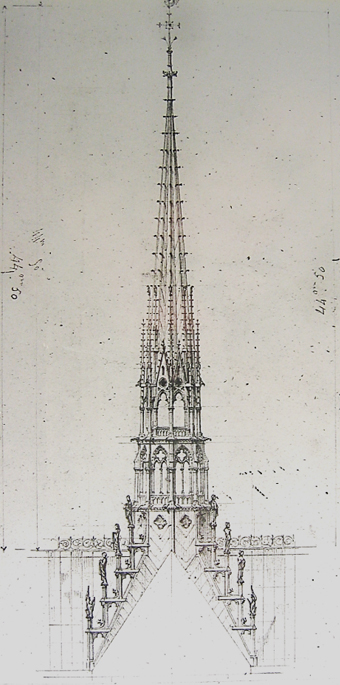

The spire 1858-1860

After a rigorous analysis of the remains of the 13th century spire, its structural failures and its scaling to the cathedral, Viollet-le-Duc designed the new spire with reinforcements to ensure better wind stability. The design shows a consummate mastery of structure and perspective, by tilting the corner posts towards the center.

"It is necessary that, in a monument so high and whose general form is so slender, all the lines tend to incline towards the axis if one wants that nothing in the whole comes to oppose the silhouette..."

As for the framework of the transept, he used the construction methods of his time: sawn timber, assembled with nuts and bolts. Thanks to the execution plans, the exact reconstruction will be possible.

Lead roofing

Lead was considered the material of the cathedrals: the most durable, the most expensive, the noblest, but also the heaviest, greatly loading the walls in conjunction with the weight of the structural framework. The lead sheets of 0,60m x 1,10m were fixed on wooden floors nailed on the frameworks and assembled according to learned techniques still in use, ensuring good dilatation.

The restitution of the frameworks, the lead sheeting on the roofs and the spire, with all their ornaments created by Viollet-le-Duc, will give back to the cathedral its pre-fire roof and an essential part of its lost authenticity.

Project for a new spire © Viollet-le-Duc, Dictionary

Stool of the spire © Viollet-le-Duc, Dictionary

Model of the spire. Compagnons du Devoir © Benjamin Mouton

Model details of the Compagnons © Benjamin Mouton

Model details of the Compagnons © Benjamin Mouton

Carpenters' axes © Rémi Fromont

Truss of the nave. Pruning a trunk with an axe © Rémi Fromont

Dressing pruning © Rémi Fromont

Punching © Rémi Fromont

Preparatory stitching for assembly © Rémi Fromont

Assembly © Rémi Fromont

Lifting © Rémi Fromont

Presentation on the square © François Calame

Spire and lead roof © Benjamin Mouton

Lead roof and ridge © Benjamin Mouton

Crest structure 19th © Benjamin Mouton

Lead roofing and ornaments of the spire © Benjamin Mouton

Lead roofing and ornaments of the spire © Benjamin Mouton